The plastic profile production process

Being a leading plastic extrusion company with more than 60 years of experience, Primo is supplying market leading industries with state-of-the art technologies in plastic extrusion. When you engage in corporation with us, you will experience high flexibility that meets the requirements for your unique solution.

WHAT IS PLASTIC EXTRUSION?

Plastic extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. At Primo, we have been extruding plastic profiles since 1959. Both extruders and the process itself have undergone significant progress over the years.

A specialised production setup

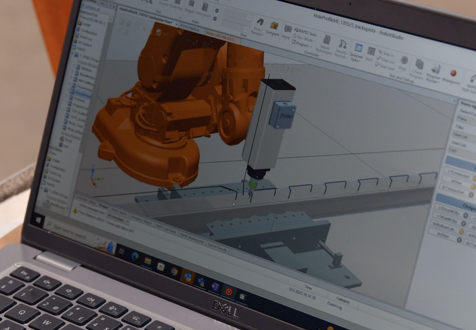

Today, advanced technology and digital monitoring ensure high-quality and cost-saving processes for the benefit of a wide range of industries and numerous applications at our highly efficient and automated production plants in Europe and in China.

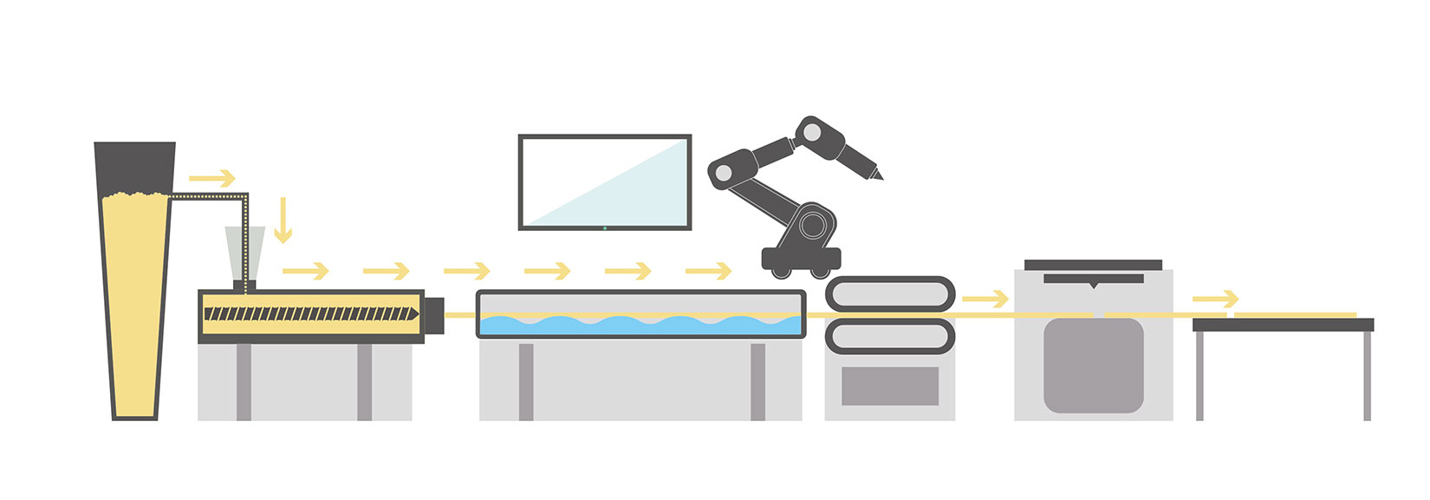

In plastic extrusion, the heated plastic mass is put under pressure by a screw and is pressed through a die (the tool). The profile is then cooled down and hardens into its final solid state. This way, a profile can be produced in any length, which is an advantage, for example, when producing parts for cables that are rolled directly onto cable reels.

Plastic profiles for all kinds of purposes

Extrusion is a widely used method to shape plastic materials, but it is also used for other materials. For instance, the technique is used to a great extent in the food industry in which products like minced meat, pasta, and even cheese puffs are made by extrusion.

CHOOSING THE RIGHT POLYMER

It is a frequently asked question - and a fairly good one - whether plastics and polymer are the same.

The short answer is no. Plastic is a polymer, but polymer is not necessarily plastic.

Plastic belongs to the polymer family

A polymer is a macromolecule composed of many similar building blocks. Plastic belongs to the family of polymeric materials. The individual types of plastic are therefore also often called polymers.

The term is derived from the Greek "polymeros", which can be translated into poly = many and meros = parts. A polymer is therefore a very large molecule - a so-called macromolecule - composed of many similar building blocks. These building blocks are called monomers.

What are plastics?

Plastics are organic materials, just like wood, paper or wool. The raw material is first and foremost crude oil. In addition, cellulose, coal, natural gas and salt are included. Crude oil is a mixture of thousands of different substances, and in order to utilize them, the oil must be refined in large plants.

5 percent of the world's oil consumption goes to plastic; the majority is used for transport.

European plastic manufacturers are organised in Plastics Europe; here you can learn a lot more about plastics.

YOU CAN FIND OUR PROFILES IN Various INDUSTRIES AND IN TECHNOLOGICALLY ADVANCED SOLUTIONS

Extrusion technology

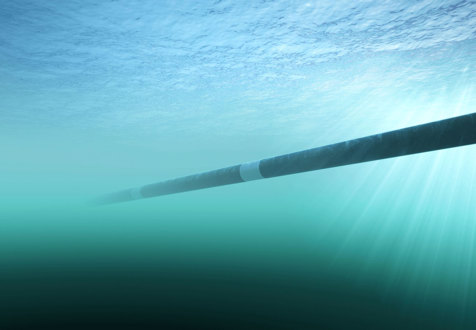

Extrusion is usually a fully automated process with continuous dimension checks and automatic machine adjustment. This makes it possible to manufacture a wide variety of products from simple tubes and rods to extremely complex window profiles. The extrusion also enables the manufacturing of very large products or practically endless profiles for use in for instance off-shore cables.

A process with indefinite possibilities

The success of the process depends on several factors in which the temperature plays a critical role. The input consists of plastics in the shape of pellets, granulates, flakes, or powder which turns into a homogenous mass when heated. Often various ingredients are mixed to obtain particular properties, such as plasticity, colour, strength, etc.

The temperature needs to be measured carefully, as well as the pressure that the screw puts on the plastic mass relative to the given plastic material and the size of the tool. Too high, too low, or too much variation in the pressure can cause tension in the final result. The stress can lead to unwanted twists in the profiles or destroy their strength.

The specific plastic type and the design of the profile also play a major role in the properties of the final solution.

Description of our steps in cooperation and achievement of your goals in business

PLASTIC EXTRUSION - A COMPLEX PROCESS WITH NUMEROUS OPTIONS

Some plastic products require more properties than a single extrusion can deliver. In these cases, co-extrusion can be an option. Co-extrusion is the process of extruding two types of plastic simultaneously through the same tool as two layers, that are fused by the influence of heat.

Co-extruding is a complex process that puts great demands on the machinery and dosage of materials from both sources. The benefit however is that single plastic profiles can have a number of properties. For instance: a rigid side for montage and a softer plastic type for airtight sealing.

In some cases, triple- and quad-extrusion can be applied. These methods require even higher degrees of precision and expertise in the dealings with the materials. Experienced extrusion companies offer such advanced production methods.

The extrusion process can also include an inlet process combining two processes in one; for instance the extruded plastic profile with a metal wire.

When the profile is cooled, further adjustments will often be made. At this point, it is possible to drill holes, add coating, and a batch number. The batch number is a quality control measure that makes it possible to go back and find details about the production conditions at a given time.

The most common types of plastics that are extruded today are polyethylene (PE), polypropylene, acetals, acrylic, nylon (polyamides), polystyrene, PVC (polyvinyl chloride), ABS (acrylonitrile, butadiene, and styrene), TPE (thermoplastic elastomers), and polycarbonate. See all material types.

Interested in other parts of our process?

Our Business Areas

Insights

Our people are dedicated to finding solutions to every challenge. That spirit makes for some great stories.

View all news & articles

Do you want to know more about our plastic panels and insulation profiles?

Jaakko Salo

Group Commercial DirectorJaakko Salo is the group's head of sales, with a broad understanding of the different markets and industries. He is also our specialist in linear lighting profiles, busbars, and diffusers: As an experienced expert in the field, Jaakko's many years of experience and contributions show his deep comprehension of the possibilities of the linear lighting landscape. He's committed to innovation in his work and has collaborated with architects, designers, and industry partners to create lighting profiles that go beyond mere functionality. Jaakko can help you shape your success and light the way for the industry.